MANAGEMENT

The Important Role of AI in Supply Chain Management & Logistics

AI was still science fiction only a decade ago. Sure, we had early chatbots and novel applications. However, today artificial intelligence literally moving the world.

Supply chain and logistic companies recently discovered the value of AI. From loading trucks to predicting the future, machine learning is posed to revolutionize the industry. But how is this happening? How does AI help move real-world objects from point A to point B?

Well, that’s exactly what we’re exploring today. We’re going to take a look at the role AI is playing in the modern supply chain and what it’s doing for logistics.

AI in Supply Chain Management

In its simplest terms, supply chain management is all activities that go into sourcing, producing, and delivering goods. The exact details will depend on the industry. For example, manufacturing supply chains focus on the process of sourcing raw materials to delivering the finished products.

Logistics are the activities within supply chain management focused on delivery and transport. How does raw material A reach point B and how does the finished product reach the customer from there? Answering that question in the most efficient and cost-effective way – that’s logistics.

Needless to say, supply chains and logistics are the very lifeblood of business, if not civilization as we know it. Grocery stores would be empty and factories would stand idle without it.

But what does this all have to do with AI?

Artificial intelligence is the simulation of human intelligence. That is what differentiates it from your standard computer algorithm. AI ingests large swaths of information and uses that to accurately predict outcomes. In our increasingly data-rich world, this has become remarkably viable across many industries – including supply chain management and logistics.

The types of AI that exist today primarily consist of artificial narrow intelligence, ANI for short. These AI focus on very specific tasks.

Here are some of the ways that technology is being used in supply chain management and logistics today:

- Demand Forecasting

- Optimizing Routing and Delivery

- Improving the Loading Process

Generative AI in Supply Chains

If you’ve heard of ChatGPT, you’ve heard of generative AI. This form of AI refers to algorithms that “generate” new information and content such as blogs and even computer code.

Demand forecasting is just one example of generative AI in supply chains. It can also be applied to automating clerical work, predicting operational results, and factoring in tariffs into operational costs. The sky is the limit for generative AI – provided that it has enough data to go off of.

For example, the company Echo Global Logistics utilizes generative AI to negotiate shipping rates, procure transportation, and automate carrier management.

Examples of AI in Supply Chain Management

With all of this in mind, let’s take a look at how AI is already assisting supply chain management and logistics.

Inventory Management

A major aspect of every supply chain is knowing what product is where and how much of it. To this end, AI has enabled companies from retail stores to mail carriers to accurately track inventory. This includes tracking orders as they move across the globe while keeping track of stored inventory via automated surveillance checks in warehouses.

AI can oversee numerous variables, including:

- Volume

- Lead time

- Temperature

- Errors

- Downtime

All of this frees staff to work on human-specific inventory tasks rather than repetitive jobs.

Demand Forecasting

Many of us joke that we’re stalked by the algorithms responsible for targeted advertisement. However, the real fact of the matter is that human behavior is predictable. Machine learning models can ingest market data to create accurate predictions of future customer behavior and automatically act on those predictions.

For supply chain management, that means predicting what will be needed where, when, and even foreseeing shortages before they happen. This ultimately reduces inventory losses and prevents out-of-stock scenarios.

Transportation Optimization

Modern customers demand fast and accurate delivery. AI-powered GPS and optimization solutions make that possible. They identify and create the most efficient of the possible routes using real-time data combined with existing map information. What’s more, they can do it in moments whereas human intelligence would have to rely on intuition and hours of mapping to come to the same conclusion.

In terms of logistics, AI can also optimize how we utilize shipping containers. Where most people see a cargo container as e a big empty box. Those in the logistics industry see an economy of space. How can we safely load a cargo container to maximize the space used? Again, AI provides a solution.

AI tools are already in use today to help optimize this space to quickly and efficiently load cargo containers and semi-trailers.

Warehouse Automation

Many warehouses, such as Amazon Fulfillment Centers, utilize AI to automate a lof their day-to-day operations. AI organizes both people and autonomous robots to store, locate and pick orders stored throughout the facility. In this system, the AI predicts where robots or human employees will be, and organize their activities accordingly.

This all creates a system where workers spend less time traversing the warehouse, and more time getting products where they need to be whether that be storing or shipping.

Customer Service

Chatbots are certainly not new technology. However, they’ve been as advanced as they are today. That’s why many companies are utilizing AI to automate a lot of their customer service activities.

Customers often come with the same concerns and questions that involve the same solutions. As such, an customer service AI has plenty of data to pull from and answer customer concerns. This saves customer representatives time from answering the same questions over and over, and allows them to focus on complex customer problems and requests outside the scope of your typical AI.

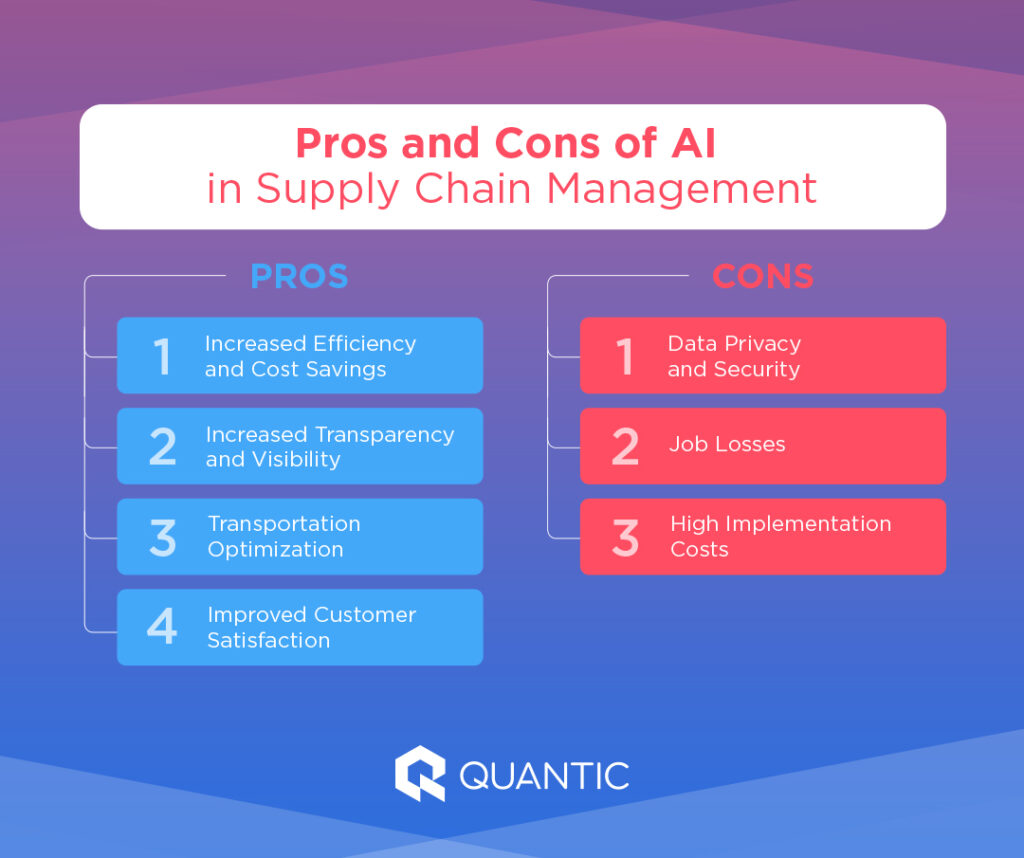

Benefits of AI in Supply Chain Management

Increased Efficiency and Cost Savings

No matter the task it’s applied to, AI can help logistics companies find the most cost-effective and efficient way to do it.

Let’s take a look at repetitive tasks like inventorying and transportation routing as examples. These tasks can take humans several hours a day to perform. AI, on the other hand, can do it in a manner of moments. Consequently, human labor is freed to focus on human-specific tasks. This improves both ROI and workers’ overall efficiency.

Increased Transparency and Visibility

When a supply chain spans the entire globe, it’s easy to see how things can get lost in the shuffle. Deliveries get lost and misplaced. Nature delays logistics. The wrong shipping label is placed on the wrong container. The list goes on.

AI helps mitigate these problems by collecting massive sets of logistic data and presenting it in a way humans can understand – and fast. That includes shipping times, inventory locations, predicted delays and shortages, and much more. For the first time in history, organizations have the potential to see the entire scope of their supply chain.

Improved Customer Satisfaction

As we mentioned before, the modern customer expects fast delivery. This is true on an individual consumer basis as it is for a B2B client. AI helps logistic companies meet that expectation.

That’s not even to mention customer service chatbots that can answer customer questions in moments rather than waiting for hours on hold to speak with an overwhelmed representative.

Disadvantages of AI in Supply Chain Management

There are very few things in life that come without drawbacks. AI is no different.

Data Privacy and Security

One of the biggest challenges to implementing AI in any industry is how data is handled. As AI solutions require massive amounts of data to create accurate results, it’s important to be conscious of where this data comes from. This is a solely human task. To AI, data is data.

Relatively new regulations, such as the EU’s GDPR, requires personal data to be handled with particular care. Otherwise, organizations risk breaking compliance, and the repercussions that entails. That means taking responsibility for how AI and machine learning algorithms utilize data.

Furthermore, there’s the matter of security. Should an AI utilize sensitive company information, it’s possible for it to unintentionally reveal that information.

That’s not even to mention the prospect of cyberattacks on AI systems. These include adversarial machine learning attacks where the system is fed to manipulate incomes and cause the AI to deliver incorrect results.

As such, we can expect growth in cybersecurity jobs that specialize in AI compliance and security.

Job Losses

It is no secret that many people fear that AI will “take their job.” And this fear is not unfounded. McKinsey predicts that automation could displace between 400 and 800 million jobs by the end of the decade. As more tasks are automated, less human labor is required, and that means companies interested in maximizing revenue will likely reduce headcount.

However, it is important to remember that this is not the first time we’ve seen this. Between the 18th and 19th centuries, we saw massive numbers of workers displaced by new machines and ways of doing things. Although it was a painful transition, society recovered quickly as new jobs appeared around these changes.

We can expect the same from an AI-tech revolution. Thankfully, unlike the industrial revolution, we can see this one coming. Professionals today can prepare by expanding their skills and education with AI-conscious courses to adapt to the new AI-driven workplace.

High Implementation Costs

AI is an amazing tool, but it comes at a cost.

For one, existing systems were not designed with AI in mind. Adapting or changing them will require significant investment. And that’s not even accounting for AI itself whose cost will depend on the level of intelligence desired as well as the processing power it will require. In fact, according to Analytics Insights, a custom AI alone could cost anywhere from $20,000 to $1,000,000.

These costs make AI out of reach for many companies today. However, like most technology, we can expect these costs to decrease as AI solutions are further developed.

Challenges of AI in the Supply Chain

Data Quality and Access

Data, data, data. If you take anything away from this, you need to know that AI is useless without data.

Providing this data is possibly the biggest challenge to implementing AI in the supply chain. As we mentioned before, legacy systems were not built with AI in mind. That means many companies will need custom solutions to take their existing data and make it available to AI solutions.

What’s more, this data will need to be available in a form that the AI can ingest and effectively use.

Resistance to Change

Change is hard. To some, it’s even scary. As such, the cultural resistance to AI that we’re seeing today is only natural.

We can divide those resisting AI into two groups: philosophical and practical.

In the practical camp, we see those who fear losing their jobs to AI; a disadvantage we just discussed. These individuals include those that work in creative industries and the clerical tasks that AI seeks to automate.

In the philosophical camp, we see those who object to AI on fundamental and ethical grounds. Here we see individuals that see AI as soulless simulations of human abilities. These critics voice concerns that AI will do more harm than good in the long term.

Regardless of their reasoning, these voices will continue to push against widespread AI implementation.

Integration with Legacy Systems

An inherent problem with any new technology, not just AI, is that existing legacy systems were developed for the technology of the time.

As such, AI systems will have trouble communicating with existing hardware and software. This poses a particular problem for large organizations that cannot simply tear their system down and build a new one. Too much important data is held in their current systems, and the cost of transferring it to a brand-new system would be astounding.

That means existing companies will need to integrate. And that means custom software development, and a good amount of troubleshooting before AI can become viable.

On the other hand, this represents an opportunity for new companies and start-ups to build systems from the ground up with AI in mind.

Overall Impact of AI in Supply Chains

We already see AI creating a positive impact on the modern supply chain, and we can only expect these benefits to grow as the technology develops.

AI has allowed us to increase the speed and accuracy of our logistical systems around the world. Shortages are anticipated. Transportation is optimized.

Supply chain managers now have enhanced visibility in their supply chain. We have a better idea of where goods are.

More and more tasks are being optimized and automated. That means we’re seeing greater ROI on the greater logistical efforts throughout the entire supply chain.

All of this ultimately means AI is pushing us to a fast, efficient, and cost-effective supply chain that was unthought of at the start of the century. And that’s only what we’re seeing today.

Future of AI in Supply Chain & Logistics

AI is still a fledgling technology. What are we seeing today is only the start of many things to come as it matures. Expect serious change to come by end of the year.�

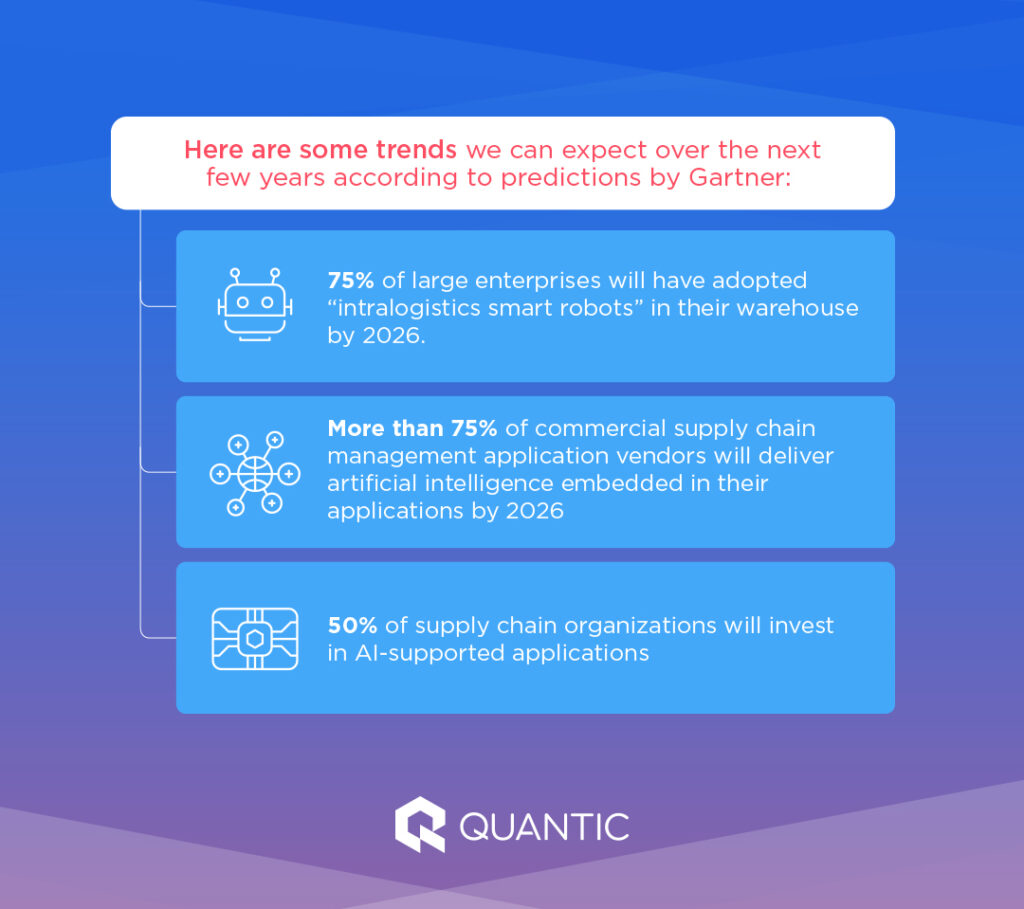

Here are some trends we can expect over the next few years according to predictions by Gartner:

- 75% of large enterprises will have adopted “intralogistics smart robots” in their warehouse by 2026.

- More than 75% of commercial supply chain management application vendors will deliver artificial intelligence embedded in their applications by 2026

- 50% of supply chain organizations will invest in AI-supported applications

And these are only predictions made for the next few years. However, the possibilities seem almost endless. For example, as AI matures alongside smart vehicles, the prospect of autonomous long-haul vehicles becomes more and more likely – a goal that companies such as Uber Freight are currently working towards.

As for what this all means for those working in the supply chain and logistics industry, we can expect a push to adopt these new technologies in the interest of efficiency and cost-effectiveness.

AI in Supply Chain Courses

The expected growth in AI over the next decade means we can expect the demand for AI professionals to grow as well. If you want to be involved, you’ll want to pursue the relevant courses and certifications today.

That’s why numerous institutions and companies are offering coursework dedicated to AI.

These include

- The United States Artificial Intelligence Insitute – Offers a certification program for AI engineers

- Coursera – Offers numerous courses on AI and deep learning.

- Harvard University – Offers multiple courses in AI and machine learning for business applications.

- Yale University – Offers a general course on artificial intelligence.

Pursuing an education with an AI in supply chains and logistics components will make you a strong candidate in this burgeoning field.

However, these organizations fail to offer where Quantic succeeds. Quantic’s MBA program offers a specialization in supply chain management that includes AI. Not only will this prepare you for an AI-driven future, but it’ll also teach you the skills to understand why it matters.

What’s more, Quantic provides an innovative tuition model to gain access to a program with accelerated career outcomes and an advanced approach to learning. That’s why Quantic outperforms both Harvard and INSEAD in terms of student satisfaction with a 61 on the NPS scale.

Apply to Quantic’s MBA program today and get ahead tomorrow.